Structure and Materials of Silver Foil Pouches

The realization method of the silver foil pouch mainly depends on the following two material structures:

1. Aluminum foil composite structure:

This is the most performance-enhanced silver foil bag. Aluminum foil is used as the intermediate barrier layer.

Common structure: PET/AL/PE or NY/AL/CPP.

Appearance: Due to the opacity of the aluminum foil, the inner surface (heat-sealing layer) of the bag will show the color, making the appearance appear as matte or semi-glossy silver white. To achieve high glossiness, the shiny PET film on the outer layer is required.

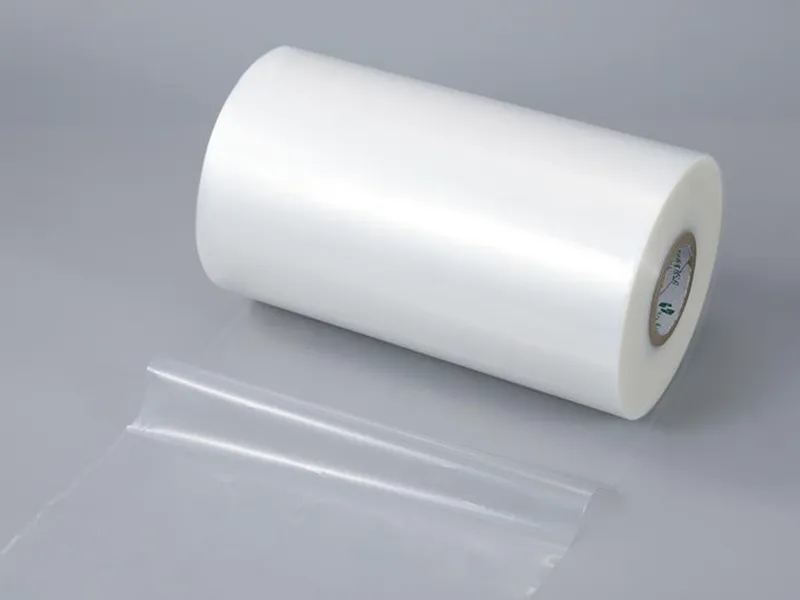

2. Aluminized film composite structure:

This is a more economical and more flexible option. Aluminized polyester or aluminized polypropylene is used on the outer layer to provide metallic luster and partial barrier properties.

Common structure: VMPET/PE or BOPP/VMPET/PE.

Appearance: Usually presents a very bright, mirror-like silver effect, with a stronger visual impact, but the barrier properties and durability are not as good as the pure aluminum foil structure.

Application Fields of Silver Foil Pouches

The silver foil pouches, with their high-end image and excellent protective properties, are widely used in:

1. High-end food and beverages:

Coffee beans/powder: Blocking light and oxygen is crucial for maintaining the flavor of coffee.

High-end snacks, nuts, chocolate: Elevating the product's quality and effectively preventing oxidation.

Milk powder, health supplements: Conveying a signal of safety and high quality, and providing top-level protection.

Seasonings, tea.

2. Electronics and industrial fields:

Electrostatic shielding bags (ESD Bag): The silver appearance is often associated with anti-static function, used for packaging sensitive electronic components and circuit boards.

Moisture-proof packaging: For camera lenses, precision instrument parts, etc.

3. Cosmetics and personal care:

Independent packaging bags for skin care products, masks, creating an impression of technology, efficiency, and cleanliness.

Hair dye, high-end shampoo refill packs.

Medicine and medical devices:

Sterile barrier packaging for drugs and medical devices that require protection from light and moisture.

What Are the Advantages and Challenges of a Silver Foil Pouch?

Advantages:

1. Outstanding brand image building: The silver foil pouch is one of the most effective packaging forms for conveying high-end, technological and modern brand positioning.

2. Top-notch protection performance: Particularly outstanding in terms of light-blocking and oxygen-blocking.

3. Strong shelf appeal: The metallic luster makes the silver foil pouch stand out among numerous packages.

4. Diverse functions: The silver foil pouch can be made into regular sealing, self-standing, with a zipper or vacuum packaging forms according to the requirements of the contents.

Challenge:

1. Higher cost: Aluminized or aluminum foil composite materials have a higher cost compared to ordinary plastic packaging.

2. Susceptible to fracture at creases: The metal layer (especially aluminum foil) is prone to develop needle-like cracks after repeated bending, affecting the barrier property.

3. Environmental and recycling issues: The separation of multi-layer composite materials during recycling is difficult. Although the aluminized film uses less aluminum, it still poses challenges for recycling.

4. Inability to display contents directly.

English

English  中文

中文